Forklift Hydraulic Repair: Leaks vs. Failures and How to Avoid Costly Downtime

Last updated: July 30, 2025

Forklift hydraulics are the core of safe lifting — when something goes wrong, your productivity, safety, and budget are all at risk. Learn how to spot the difference between small leaks and catastrophic system failures, and how professional hydraulic repair services in Orlando and Raleigh can prevent major damage.

Let’s say you arrive at the warehouse and see a slow drip from your lift truck. You wipe it, ignore it, and keep working. Within weeks, that drip turns into a burst hose — shutting down your only machine during peak hours. At AAA Forklifts, we see this scenario far too often. That’s why we wrote this guide: to help you stay ahead of costly repairs.

Minor Hydraulic Leaks: The Silent Productivity Killers

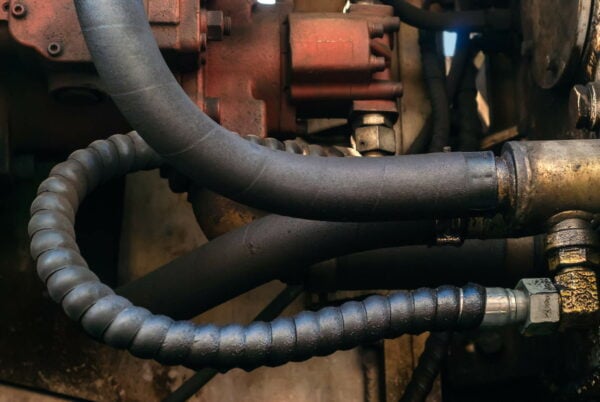

That small puddle under your forklift? It's more dangerous than you think. Minor leaks often escalate into major repairs when ignored. These are common issues we see in our hydraulic hose repair services.

Common Causes of Hydraulic Leaks:

- Worn hose fittings or seals – Over 60% of minor leaks we service stem from fatigued rubber or brass connectors. These degrade over time due to vibration and pressure cycling.

- Hairline cracks in steel tubing – Often invisible to the eye, small cracks form in high-pressure return lines due to corrosion or impact damage.

- Loose connections – Vibration and poor maintenance can loosen threaded connections, especially near the mast or hydraulic reservoir.

- Aging O-rings – Exposure to heat, contaminants, and age degrades internal seals, especially those behind valves and cylinders.

Why immediate action matters: A $150 seal replacement today prevents a $4,000 pump failure tomorrow. Leaks reduce system pressure by up to 30%, forcing components to work harder and increasing wear. One of our Orlando customers learned this the hard way when a slow drip resulted in a full lift chain collapse mid-shift.

Catastrophic Hydraulic Failure: Recognizing the Red Flags

These symptoms mean your hydraulic system is failing right now:

- Sudden loss of lifting power – Often the result of a collapsed pump rotor or internal valve blockage.

- Loud whining/screeching – Cavitation inside the pump due to air intrusion or low fluid levels.

- Foaming hydraulic fluid – A clear sign of air mixing into the system, often through leaks in suction lines.

- Intermittent shutdowns – Thermal overloads in the pump motor or pressure-relief valve failures may be triggering system cutoffs.

Emergency response tip: Shut down immediately if you see these signs. Continuing operation can cause irreversible damage. One Raleigh-based client who ignored the signs ended up needing a full hydraulic pump rebuild that sidelined their forklift for 4 days.

The True Cost: Leak Repair vs. System Failure

Compare the time, money, and productivity lost depending on when you catch the problem. Many hydraulic failures stem from ignored leaks or skipped maintenance.

| Issue | Repair Cost | Downtime | Preventable? |

|---|---|---|---|

| Leaking Hose | $150-$300 | 1-2 hours | Yes |

| Pump Failure | $2,000-$4,000 | 2-4 days | Yes (if caught early) |

| Cylinder Rebuild | $600-$1,200 | 2-3 days | Often |

| System Contamination (Flush Neglect) | $1,000-$2,000 | 2 days | Yes |

5-Minute Hydraulic Check (Do This Every Shift)

Just five minutes a day can save thousands. Our technicians recommend these daily visual and operational checks:

- Inspect hoses/cylinders for wet spots or seepage

- Check beneath the forklift for signs of dripping fluid

- Listen for new noises: whining, screeching, or thumping

- Test lifting and tilting speed to spot lag or hesitation

- Verify reservoir levels and check fluid color (milky = contamination)

Free Professional Inspection

Our certified technicians will perform a 120-point hydraulic system check at no cost.

AAA Forklifts Hydraulic Services

Emergency Repairs

Same-day hydraulic hose replacement and seal repairs to minimize your downtime.

Cylinder Rebuilds

In-shop or mobile cylinder rebuilds with full resealing and pressure testing.

System Flushes

Remove contaminants and prevent premature wear on pumps, valves, and cylinders.

Control Valve Resealing

We repair and reseal hydraulic directional valves to eliminate internal bypass and pressure loss.

Free Hydraulic Maintenance Checklist

Download our printable checklist used by techs in Orlando and Raleigh to spot leaks, pressure loss, and contamination risks.

Need Hydraulic Help Now?

Deja un comentario

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.