How to Prevent Forklift Hydraulic Hose Failure

One hydraulic hose failure can shut down your entire forklift — and your business with it. These high-pressure lines are essential to lifting, tilting, and steering. When they rupture, it’s not just inconvenient — it’s dangerous and expensive.

This guide will show you how to recognize early warning signs, keep your equipment running smoothly, and avoid downtime and costly repairs.

🔧 Pro Tip: Rotate hoses during preventive maintenance to distribute wear evenly.

1. Common Causes of Hydraulic Hose Failure

Hydraulic hoses on forklifts endure intense pressure, extreme temperatures, and constant movement. Over time, this leads to wear, cracking, and eventual failure. The most common causes include:

- Abrasion: Hoses rubbing against components or each other

- Heat degradation: Caused by proximity to hot engine parts or sun exposure

- Improper routing or clamps: Leads to unnecessary flexing and pressure

- Fitting issues or poor crimping: Results in leaks and line blowouts

- Age: Even the toughest hoses have a service life (typically 5+ years)

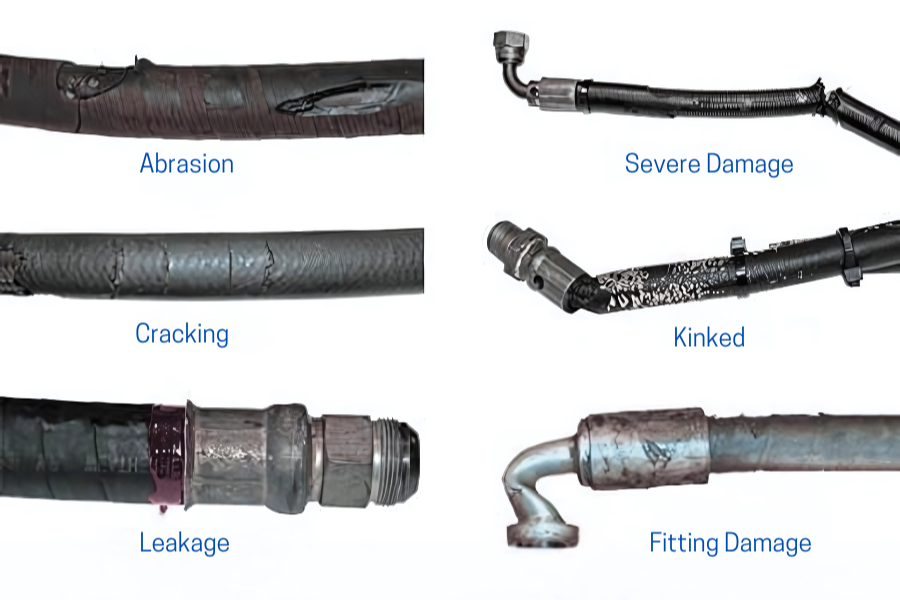

2. Early Warning Signs You Should Never Ignore

Daily visual inspections are key to preventing hose failure. Here’s what to look for:

- Cracks or blisters along the rubber outer layer

- Leaking fluid around fittings or joints

- Wet or oily residue on the hose itself

- Rusty or corroded fittings (a sign of impending failure)

- Visible steel reinforcement wire (means the outer layer is compromised)

⚠️ If you notice any of these symptoms, remove the forklift from service immediately and contact a hydraulic repair specialist.

3. Preventive Maintenance Checklist

At AAA Forklifts, our 120-point forklift inspection reduces hydraulic failure risk by over 60%. Here’s what we recommend:

- ✅ Inspect all hydraulic lines weekly for wear

- ✅ Replace hoses before their rated lifespan ends

- ✅ Keep hoses clean and free of debris buildup

- ✅ Verify proper routing and clamp positioning

- ✅ Check hydraulic fluid levels monthly

4. Don’t Forget Hydraulic Tailgates & Attachments

Many delivery trucks and fleet vehicles use hydraulic tailgates or liftgates. These hoses often fail due to:

- Outdoor UV exposure

- Infrequent maintenance

- Improper storage when not in use

We service these too—both in-shop and on-site.

🎯 Get a FREE 120-Point Forklift Inspection

Mention code JUNEPM this month for a complimentary full inspection. We’ll check:

- Every hydraulic hose and fitting

- Cylinders and seals

- Fluid levels and contamination

5. Why Professional Repair Matters (Don’t DIY This!)

Hydraulic hose repair requires specialized tools and expertise. Here’s what our certified technicians provide:

- Pressure-tested replacements built to exact PSI specs

- On-site mobile service to minimize downtime

- Safety-first installation with proper torque and routing

Whether you're in Orlando, Tampa, or Central Florida — or need forklift service in Raleigh, NC — our team is ready to help.

📞 Call Now:

Deja un comentario

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.